In a world where the old makes way for the new with each passing day, the significance of rejuvenating existing surfaces cannot be overstated. Precision surface renewal stands at the forefront of this transformative journey, heralding a future where renewal is not just about replacement but about revitalization and improvement. This comprehensive exploration delves into the essence of precision surface renewal, its methodologies, benefits, and the diverse applications that make it an indispensable part of modern maintenance and manufacturing processes.

The Genesis of Surface Renewal

The concept of surface renewal is as old as time itself. Nature has its way of renewing surfaces through processes like erosion, sedimentation, and the life cycles of flora and fauna. Inspired by these natural phenomena, humanity has developed its own methods to renew, restore, and rejuvenate surfaces to extend their lifespan, enhance their appearance, and improve their functionality.

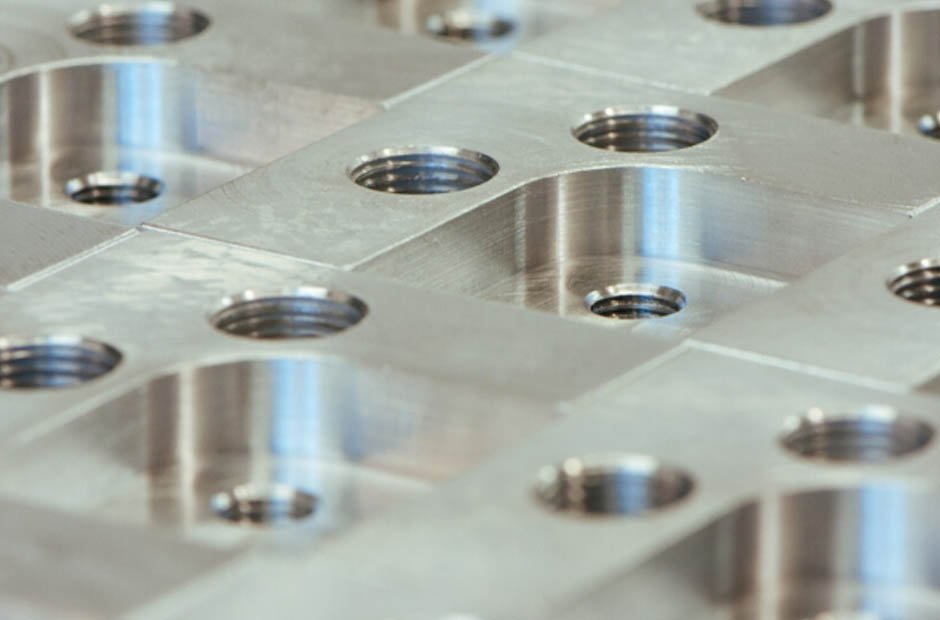

At its core, precision surface renewal is about applying controlled techniques to refine the surface of materials. These techniques vary widely, from simple manual sanding to sophisticated laser ablation, catering to the needs of different industries and materials.

A Spectrum of Techniques

The world of precision surface renewal is vast, encompassing a variety of techniques designed to meet specific requirements. One such method is abrasive cleaning, a technique that meticulously removes surface impurities without compromising the integrity of the material. This method is a testament to the balance between aggression and precision, a crucial factor in the success of surface renewal efforts.

Beyond abrasive cleaning, there are numerous other techniques like chemical etching, where chemicals are used to refine or modify the surface of materials. Then there’s thermal spraying, a process that applies coatings to surfaces to protect them from wear and corrosion or to imbue them with specific properties.

Each method in the spectrum of precision surface renewal serves a unique purpose, from restoration and preservation to enhancement and protection, highlighting the versatility and adaptability of these techniques to various scenarios.

The Renaissance of Materials

Precision surface renewal is akin to a renaissance for materials, breathing new life into surfaces that might otherwise be deemed beyond their prime. This renewal process can significantly extend the life of materials, reduce waste, and lower the environmental impact by minimizing the need for new materials.

In the realm of architecture and heritage conservation, precision surface renewal plays a pivotal role in preserving the integrity and authenticity of historical structures. It ensures that these cultural treasures can withstand the test of time, maintaining their historical significance for future generations.

In manufacturing, the renewal of tooling surfaces leads to increased efficiency, reduced downtime, and lower costs. This is crucial in industries where precision and reliability are paramount, such as aerospace, automotive, and medical device manufacturing.

The Green Advantage

One of the most compelling benefits of precision surface renewal is its contribution to environmental sustainability. By refurbishing and reusing materials, the demand for raw resources is reduced, as is the energy consumption associated with the production of new materials. This not only conserves natural resources but also reduces carbon emissions, contributing to the global efforts against climate change.

Furthermore, precision surface renewal technologies are continually evolving to become more energy-efficient and less reliant on harsh chemicals, further enhancing their environmental credentials.

A Canvas of Possibilities

The applications of precision surface renewal are as diverse as they are innovative. From the refurbishment of vintage cars to the restoration of weathered monuments, and the maintenance of industrial machinery, the potential is boundless.

In the realm of space exploration, precision surface renewal techniques are used to ensure that spacecraft can withstand the harsh conditions of space travel. In the medical field, they are used to refurbish surgical instruments and medical devices, ensuring safety and reliability.

The Path Forward

As we continue to explore the capabilities and potential of precision surface renewal, it is clear that this field will play a crucial role in the future of maintenance, manufacturing, and conservation. The ongoing research and development in this area promise even more advanced techniques and applications, making precision surface renewal an exciting field to watch.

The journey of surface renewal, from its natural origins to its current technological advancements, is a testament to humanity’s ingenuity and resilience. By embracing these techniques, we can ensure that the old can be transformed, preserved, and cherished, paving the way for a future where renewal is synonymous with sustainability and innovation.

Eradicating the old through precision surface renewal is not just about making things look new again; it’s about embracing the past, improving the present, and paving the way for a sustainable future. This journey of transformation and rejuvenation highlights the balance between preserving our heritage and embracing technological advancements. As we continue to explore and expand the horizons of precision surface renewal, we are reminded of the incredible potential that lies in giving new life to old surfaces.